Building Information Modelling

Our Summary

As part of a wider strategy for digital integration, TGA developed internal processes and systems to become leaders in Building Information Modelling. By maintaining investment in internal training & development, technology and software, at the same time as building a portfolio of true BIM projects, TGA are at the forefront of MEP design.

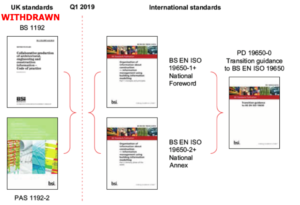

The internal processes put in place by TGA since adopting a BIM approach in 2011 follows the principles of PAS1192 and the UK Government mandate implemented in 2016. As part of this, TGA became accredited to PAS1192 by a UK Accreditation Service to deliver Level 2 projects.

More information is available on our BIMTS website: www.bimts.co.uk

BIM is a process that can bring major benefits to the design, construction and operation of buildings and their maintainable assets. To realise the benefits of BIM however, there needs to be a clear understanding of the project’s digital aspirations, not just by the design team, but also by the constructors, maintainers and end users.

Collaboration is key in achieving a success on any project. Collaboration between design team members, constructors, operators and end users is not new. BIM should certainly not be seen as trying to introduce ‘collaboration’, it should already exist. It is, however, a method of reinvigorating and improving communication on all projects for understood project deliverables, objectives and targets.

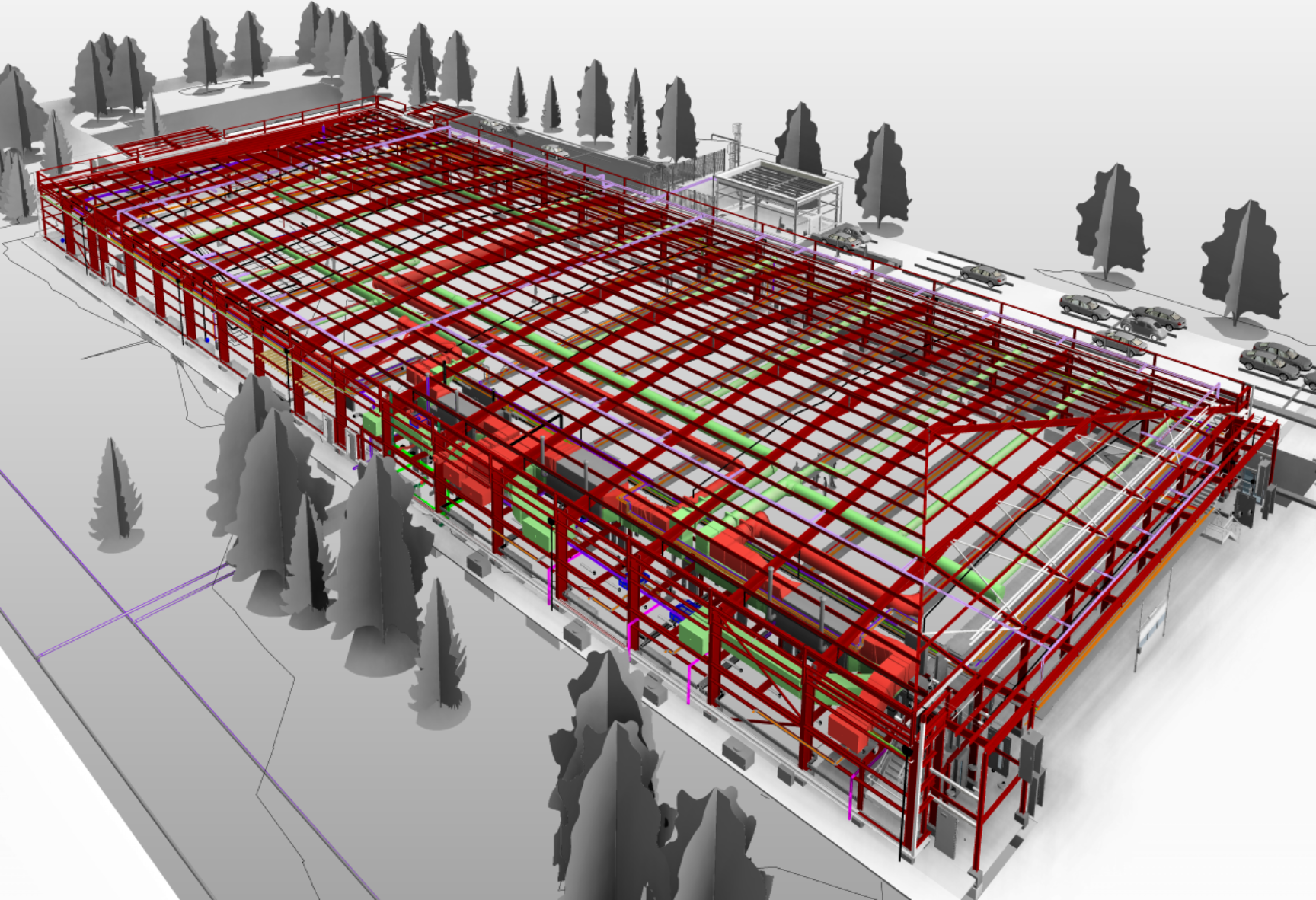

Whilst the use of a formal BIM process is often required, there are also projects where the use of 3D modelling may prove effective in its own right.

As TGA are often commissioned on schemes where a formal BIM process is not being followed, it is crucial that the benefits or 3D modelling can still be achieved. This includes for example, the ability to transfer models between calculation tools or the use of clash detection tools to assist with space planning and overall coordination.

Whilst not formally BIM, the use of modelling still proves effective and allows TGA to remain efficient in their design development.

The role of the design team in the development of modelled information, the level of detail, suitability for ongoing use and ability to retain or hold data are often areas that are misunderstood.

This is very often the case on Design & Build Schemes where a level of design responsibility is moved across to the construction team for design completion. With in-house expertise, TGA can offer a Due Diligence review of modelled information to ensure that it is suitable for continued use.

Where the modelled MEP information is not to the required level of detail or contains major clashes or is simply inadequate, this can be quickly highlighted for review, with the associated risk being allocated.

As part of an ongoing role, TGA can also provide the completion of a model as part of final design development stages, including for example, a fully coordinated technical design model or installation model.

The internal development of engineers at TGA and their ability to digitally engineer MEP models is more important now than ever. The use of digital engineers offers TGA major benefits over the typical development of creating virtual models in various software applications, with engineers now working more continuously within the MEP Revit model, developing analysis and calculations as well as setting out systems and components.

TGA use MagiCAD tools, as well as IES Virtual Environment and SketchUp to work seamlessly with Revit, helping to improve the link between engineering and modelling, resulting in better developed, coordinated MEP models.

Using an in-depth suite of integrated analysis tools, the specialist Digital Modelling Team (part of the Building Performance Team) develop building specific models for full thermal analysis, Building Regulations Compliance, Energy Performance Certificates etc.

Through the use of accurate model building, analysis including Solar, Energy and Carbon, Lighting and Daylighting, Airflow and Climate, can all be undertaken to ensure that the required design criteria and compliance requirements are achieved.

The importance of 2D design and 2D drawn information must not be ignored. Although there is a shift to develop design information in 3D in order to minimise on-site clashes and improve design efficiencies, it is still via the use of 2D drawn information that much of this information is relayed, including typically how contractors construct buildings.

Using our experienced CAD Team, we offer 2D CAD services including general drawing production and As Built Drawing creation.

We can provide an engineered approach to the creation of data rich family components that align with industry guidelines and requirements.

This service allows for generic family components to be developed and then utilised in 3D modelling, rather than relying on manufacturer’s components that are often without the required IFC / COBie parameters and / or developed by those who are more interested in appearance than function.